Waste Management

Enery Recovery Technology - Zero-Residue Conversion of Unsegregated Municipal Solid Waste & Hazardous Bio-medical Waste using ERT (Energy Recovery Technology)

- Solution for Covid-19 related Waste Disposal Problems

- No Segregation

- No Carbon Emissions

- No Post-process residue

- Automatic and complete conversion of waste to Energy Products

- Made in India Technology

- Member of India Sanitation Coalition, Task Force for Best Practices India Sanitation Coalition is an initiative by FICCI, put together to assist the Government in facilitation and proper implementation of the Swatch Bharat Mission and the Sansad Aararsh Gram Yojana (SAGY) programs.

- Listed in SWACHH Portal of Urban Development Ministry

- Business Development Associate of Indian Institute of Toxicology Research (IITR) Lucknow for sewage treatment technologies.

- Consultant/Advisor at Malaviya Center for Innovation, Incubation and Entrepreneurship ( MCIIE), at Indian Institute of Technology ( IIT), BHU (Banaras Hindu University)

- The Waste treatment technology ERT (Energy Recovery Technology) promoted by Observing I Ecotech is the property of OIE Partner, Mr Ravi Nafde.

- ERT has been designed, developed and optimized by Mr.Ravi Nafde.

- He is recognized in India as a pioneer of Design & Engineering for Energy Recovery Plants.

- He is a degree holder in Architectural Design from VRCE (now known as VNIT), Nagpur and has also pursued Industrial Design from IIT Powai, Mumbai

- ERT, a breakthrough technology, has been closely vetted and assessed by the R&D Department of Indian Oil Corporation. The technology has been successfully demonstrated to Pollution Control Board Authorities in Uttar Pradesh, Uttarakhand, Goa & Maharashtra for conversion of BIO-MEDICAL WASTE and UNSEGREGATED SOLID MUNICIPAL WASTE.

- Safe disposal of msw & biomedical waste is a serious concern for the government of india!

- Incineration of plastic waste is a common practice and a major source of air pollution. Biomedical waste and Municipal Solid Waste containing about 12% to 30% of plastics is burnt, releasing toxic gases which pollutes air, pose a threat to vegetation, animal health and environment as a whole. It contains toxic compound which causes cancer, neurological damage, disrupts reproductive thyroid and respiratory systems.

- Landfills in India and around the globe are reaching capacity.

- Not only land public awareness of plastic in ocean has also increased.

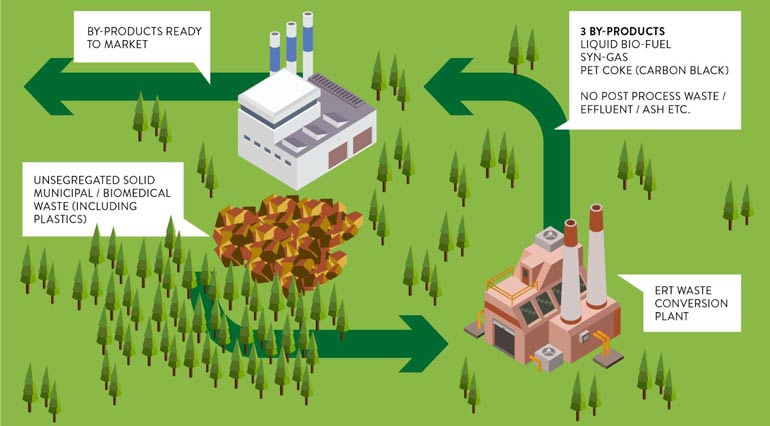

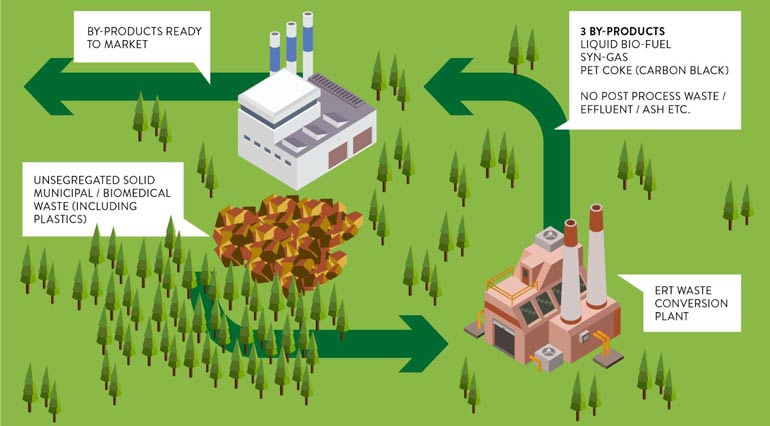

- ERT ( Energy Recovery Technology)

- Environmentally safe conversion of waste –to energy products

- Unsegregated Municipal and Biomedical waste can be converted to HYDROCARBONS

- Yelding liquid fuel, SYN-gas and PET coke, without any pollution to the environment or any further waste residue!

- It is the only solution available to address problems OF Plastics, Unsegregated Municipal Waste and Hazardous Biomedical Waste

- Processes all types of Waste ( including non recyclable plastics) and other wet waste together

- Most technologies currently available for conversion of plastic to energy have proved to be commercially unviable, due to costof segregation of waste, use of gas in the process and non-biodegradable RESIDUE

- Capital and Running costs are significantly lower than most technologies available

- Uses continuous system of processing which is more productive and efficient than the batch system used by foreign technologies. Most significant is non-build up of waste, thereby no stench and NO land pollution

- Plant can be built according to the requirements -ranging from a 250 Kg/day to a 10,000 TPD plant

- Plant design Reduces formation of coke by extruder-screw self-cleaning function

- Plant design allows Inline separation of solid wastes

- Plant Design allows flexibility of changing feed design and thereby producing desired end products

- Governments and private industries are highly motivated to get rid of land fills.

- In India specially in big metropolitan cities landfills have reached to your nearby neighbourhoods.

- None of the current solutions are giving results.

- Cutting costs and efforts of segregation which is the most tedious process.

- Using of the by-product makes ERT the most economic solution for the major challenge of waste management.

- Observing I is giving end to end solution to the problem under one roof.

- No pollution control system is required. control systems are provided for monitoring and feed back

- There is no direct exposure for the staff, since all operations can be monitored remotely

- There is no reason to cause back fire, as the process is chemical reaction and not burning

- There is no particulate matter in the emission. the emission is only burned gases.

- The maximum temperature requirement is 350°c to 500°c hence very low energy is consumed

- No emissions under the controlled operational conditions.